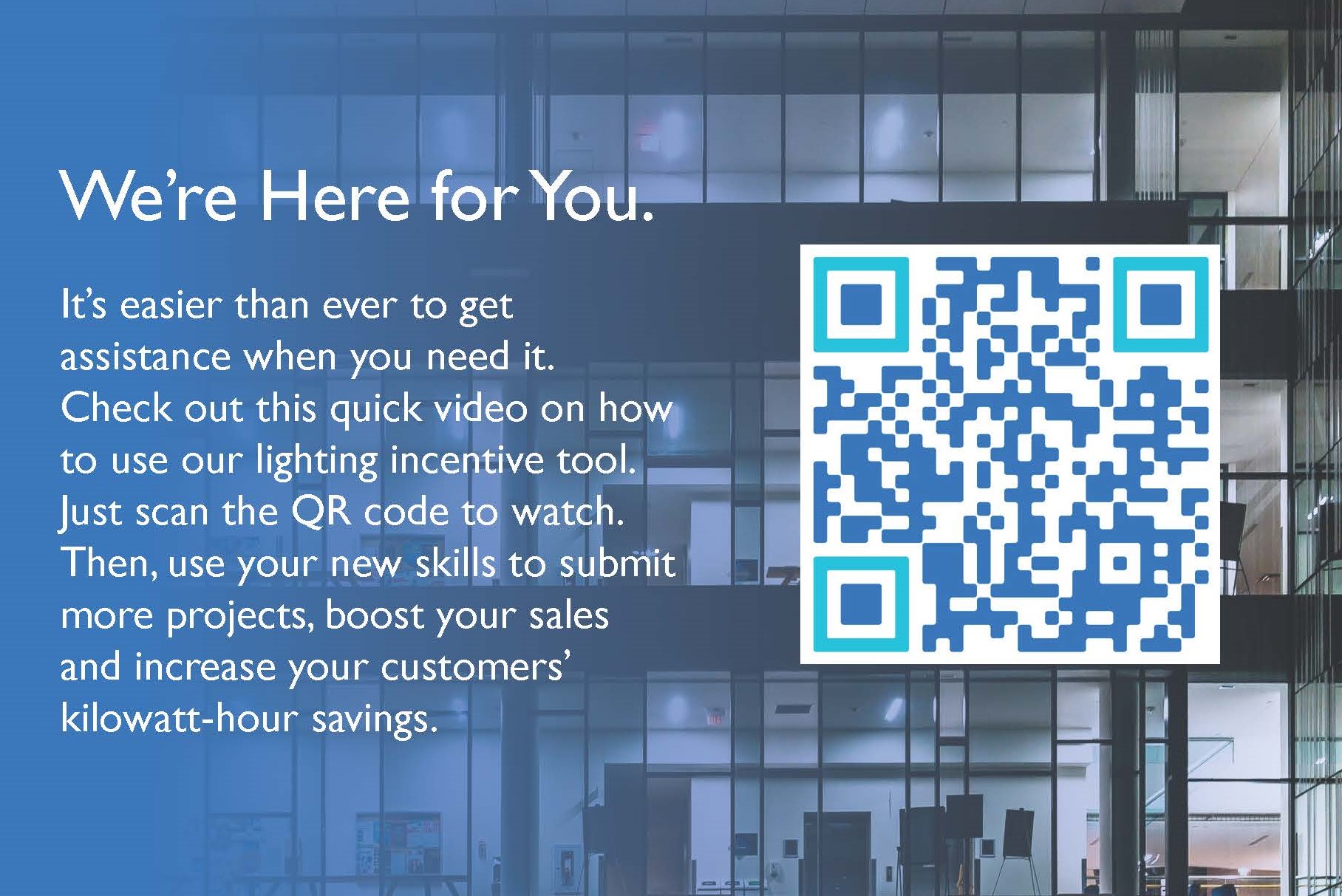

Random cold-calling can be time-consuming. That is why the Wattsmart team has targeted specific businesses that may be unaware of the Wattsmart savings opportunities but could benefit from an upgrade.

Summer is the perfect time to talk to local charter schools about energy efficiency opportunities. To support our vendors in this endeavor, postcards went out to Idaho and Wyoming charter schools in June. The message was that now is a good time to reduce operating costs.

An additional group we mailed to recently is health services—doctors, dentists, physical therapists, laboratories, etc. Upgraded lighting can vastly improve patients’ experiences. Others we plan to contact include auto repair shops and eating/drinking establishments.

Wattsmart has proactively reached out to these customer segments in an effort to generate leads for you, our vendors. After we identify an opportunity, the first question we ask a customer is if they have a preferred vendor. If they do not, we refer them to our Premium Vendor Network. It pays to be Premium!

If you have existing customers that fall into these categories, now is a great time to reach out to them again to see what energy efficiency opportunities may exist. Below are links to the cards that were already sent. You can print them out and present them when you visit any of these businesses. Contact the Wattsmart Business team if you need support with this or any other program.